Top 10 Issues & Resolutions in Concrete Leveling

Issues you're facing in concrete leveling include uneven surfaces, moisture-related problems, shrinkage, inadequate compaction, and scaling. Solutions range from prompt attention to leveling, use of sealants, controlling water-cement ratios, employing proper tools for compaction, to implementing quality concreting practices. Other common problems like discoloration, dusting, and spalling also have viable fixes such as altering cement type, regular cleaning, or concrete resurfacing. Approaching these issues strategically can enhance longevity and aesthetic appeal. Keep going—you're on the right track for more concrete insights!

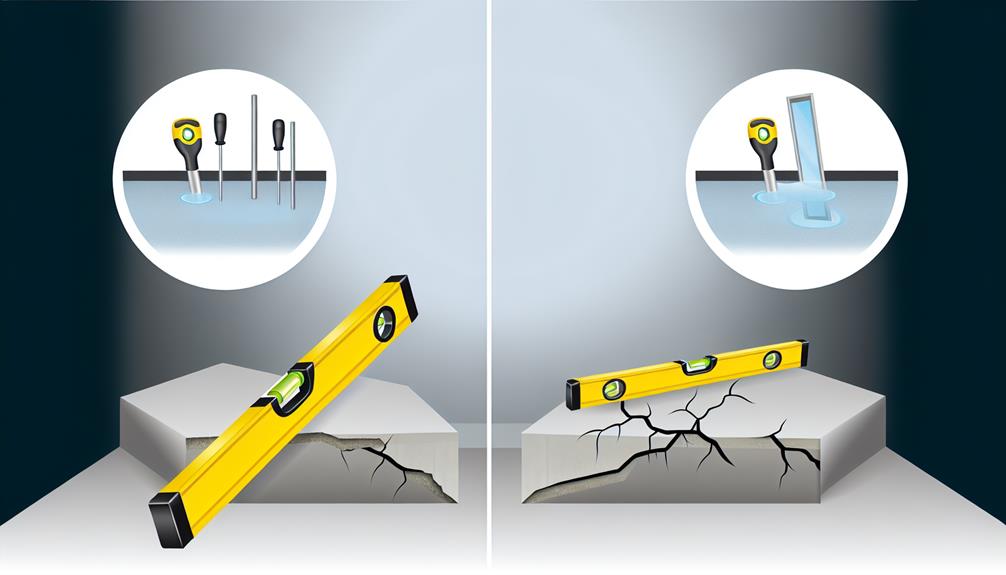

Uneven Concrete Surface Problems

Ever faced the issue of an uneven concrete surface in your home or workplace? It's not just an aesthetic concern, it's a safety hazard too. You could trip on an uneven surface and hurt yourself.

This problem is often caused by settling or sinking concrete. As the ground underneath the concrete shifts over time, it can cause the surface to become bumpy and uneven. You might notice that one side of a concrete slab is higher than the other, or that there are cracks or bumps in the surface.

You might think it's just a minor inconvenience, but it can actually cause pretty significant problems. If it's in a high-traffic area, it's a tripping hazard. And if it's a surface you drive on, like a driveway or a garage floor, uneven concrete can actually damage your vehicle.

The good news is, it's generally a fixable problem. But it's not something you should ignore or put off. You don't want to wait until someone gets hurt or property gets damaged to address it. So, if you spot uneven concrete around your home or workplace, take action. But remember, we aren't discussing solutions yet, that's for the next subtopic.

Solving Moisture-Related Issues

One of the first things you'll need to tackle when leveling concrete is addressing any moisture-related issues that could be contributing to the problem. Moisture can lead to several issues, such as concrete discoloration, cracking, and even structural damage. It's crucial to identify and address these issues early to prevent further complications.

To help you understand better, let's break down common moisture-related problems, their causes, and potential solutions in a simple table:

| Problem | Cause | Solution |

|---|---|---|

| Discoloration | High moisture content | Use quality sealants |

| Cracking | Water seeping into cracks | Apply waterproofing compounds |

| Structural Damage | Long-term water exposure | Implement proper drainage |

Once you've identified the issue and its cause, you can then take the necessary steps to solve it. For instance, you might need to use high-quality sealants to prevent discoloration, apply waterproofing compounds to stop water seeping into cracks, or implement a proper drainage system to avoid long-term water exposure.

Addressing Concrete Shrinkage

After tackling moisture-related issues, your next concern should be concrete shrinkage, a common problem often overlooked in concrete leveling projects. Shrinkage occurs when water in the concrete mix evaporates, causing the concrete to contract and form cracks. It's not just an aesthetic issue, it can also compromise the structural integrity of your project.

Here's how you can address it. First, ensure you're using the right water-cement ratio. Too much water will result in more shrinkage. So, measure carefully and don't skimp on quality cement.

Next, consider adding shrinkage-reducing admixtures to your concrete mix. These products can significantly reduce shrinkage and the risk of cracking.

Third, control joints are your friends. These are planned cracks that allow the concrete to shrink without causing random cracks elsewhere. They should be a part of any concrete project.

Lastly, proper curing is critical. This isn't about speed-drying your concrete – quite the opposite. Slow, controlled drying reduces the risk of shrinkage and strengthens the end result.

Remedies for Inadequate Compaction

Moving on to another crucial issue in concrete leveling, let's talk about inadequate compaction and how you can effectively remedy this problem.

Inadequate compaction can lead to numerous issues such as settling, cracking, or even failure of the concrete structure. But don't worry, there are quite a few solutions to this problem.

Firstly, always ensure that you're using the right tools. Hand tampers or plate compactors are usually perfect for small areas, while larger areas may require a roller.

Secondly, pay close attention to the moisture content of the concrete mix. Too little moisture can hinder proper compaction, while too much can lead to segregation or bleeding. You'll have to find the 'Goldilocks' zone – not too wet, not too dry.

Lastly, don't forget to consider the subgrade. If it's not compacted properly, even the best-laid concrete can fail. It's worth spending extra time to compact the subgrade to the right degree.

Overcoming Concrete Scaling Issues

Let's tackle another common problem you might encounter in concrete leveling: concrete scaling. This issue arises when the surface of your concrete starts peeling, chipping, or flaking away. Often, it's due to exposure to freezing and thawing cycles, deicing chemicals, or poor finishing techniques.

To overcome this, you need to identify the cause first. If it's due to weather, consider using a concrete sealer. This product provides a protective layer, shielding your concrete from harsh conditions. If deicing chemicals are to blame, try to minimize their use or opt for less damaging alternatives.

Poor finishing techniques can also result in scaling. For instance, overworking the surface or adding too much water can weaken it. To resolve this, ensure you follow proper concreting methods. If you're unsure, it's best to consult with a professional.

Lastly, remember that prevention is better than cure. Regular maintenance and proper installation are key to avoiding scaling issues. Don't skip these measures in a bid to save time or money; you'll likely end up spending more in the long run.

With these tips, you'll be well-equipped to overcome any concrete scaling issues that come your way. Stay tuned for our next topic: 'Tackling Cracking Concrete Problems'.

Tackling Cracking Concrete Problems

While concrete scaling is a common issue, cracking concrete is another problem you might face that can seriously compromise the integrity of your structure. Cracks can appear due to several reasons, from natural wear and tear to poor concrete mix or incorrect curing process.

Here's how to tackle this issue. First, you'll need to identify the type of crack. Is it a hairline crack, a structural crack, or a settlement crack? Each demands a different approach. Hairline cracks can often be sealed using a concrete sealer. This prevents water from seeping in and causing further damage.

On the other hand, structural and settlement cracks are more serious. You'll typically need to call in a professional for these. They may suggest options such as epoxy injection, stitching, or even a complete slab replacement.

Concrete Curling: Solutions Explored

Another issue you may encounter with concrete is curling, a problem that arises when the edges of a concrete slab start to rise or curl up. This is typically caused by uneven drying rates between the top and bottom of the slab. When the top dries faster than the bottom, it shrinks, causing the slab to curl.

Addressing this issue requires a few strategic steps. Firstly, ensure that the concrete mix is consistent throughout. You don't want to have different drying rates within the same slab. Secondly, control the environmental conditions during the curing process. Avoid direct sunlight and wind, and maintain a consistent temperature.

You can also consider using a curing compound to slow down the drying process, thus reducing the risk of curling. Additionally, proper joint placement can help control where the concrete will crack, preventing curling.

Dealing With Concrete Discoloration

Concrete discoloration, a common eyesore in structures, can be a real headache if you're not armed with the right knowledge to tackle it. This problem usually arises due to variances in the type or amount of cement used, changes in mix proportions, or the use of calcium chloride as an accelerator during the curing process.

It's crucial to find the right solutions to fix this, and you're in luck because we've got some effective methods lined up for you.

| Cause of Discoloration | Solution |

|---|---|

| Variances in cement type | Use a uniform batch of cement |

| Changes in mix proportions | Maintain consistent mix proportions |

| Use of calcium chloride | Use non-chloride accelerators |

Concrete Dusting: Effective Measures

If you've noticed a powdery substance on your concrete surfaces, you're likely dealing with a problem known as concrete dusting, and we're here to guide you through effective measures to tackle it.

Concrete dusting can be a nuisance, but with the right approach, it's something you can manage. Here are some measures to consider:

- Proper Finishing: Ensure your concrete is properly finished. It'll prevent dusting and increase the lifespan of the concrete.

- Use of Quality Concrete: Not all concrete is created equal. Use high-quality concrete with sufficient cement to prevent dusting.

- Seal the Surface: Apply a concrete sealer to the surface. It'll bind the concrete particles together, reducing dusting.

- Regular Cleaning: Regularly clean your concrete surfaces to remove dust particles before they accumulate.

- Professional Help: If dusting persists, consider hiring a professional. They'll know how to deal with the issue effectively.

Solutions for Concrete Spalling

Dealing with spalled concrete might seem daunting, but don't worry – there are effective solutions to this common issue. Spalling, characterized by chipping, flaking, or crumbling concrete, can quickly degrade the look and longevity of your surfaces. Here are some ways you can address this issue.

First, you can remove the damaged concrete. Using a hammer and chisel, you can chip away the spalled concrete until you reach a sound surface. It's hard work, but it's necessary to ensure the repair material adheres properly.

Second, you can apply a concrete resurfacer. This solution is designed to bond with the existing concrete and form a new, smooth surface. It's a great way to fix minor spalling and prevent further damage. Remember to follow the manufacturer's instructions for the best results.

Lastly, for severe spalling, you might need to consider replacing the entire concrete slab. It's a major undertaking, but it will provide a long-lasting solution.

Frequently Asked Questions

What Are the Costs Associated With Concrete Leveling?

You're probably wondering about the costs associated with concrete leveling. It's hard to give an exact figure without knowing your specific situation, but generally, it can range from $500 to $2000. Factors like size of the area, condition of the concrete, and type of leveling method can greatly influence the price.

It's important to get several quotes from different professionals to ensure you're getting a fair deal. Don't forget, investing in proper leveling can save you money in the long run.

How Long Does the Concrete Leveling Process Typically Take?

Ever thought about how long concrete leveling takes? It's not as time-consuming as you might think. In most cases, the process can be completed in a day or less.

However, it's not just about time, it's about conditions, too. Weather and the size of the area being leveled can affect the timeframe.

It's best to discuss specifics with your contractor to get an accurate estimate. Remember, good things come to those who wait.

Are There Any Preventative Measures to Avoid Common Concrete Issues?

Yes, there are preventative measures you can take to avoid common concrete issues. Regularly sealing your concrete can prevent damage from water, oil, and UV rays.

You should also remove stains immediately to keep them from soaking in. Avoiding excessive weight on the concrete can prevent cracking.

How Does Weather or Climate Affect Concrete Leveling and Its Associated Problems?

Weather and climate significantly impact concrete leveling. In extremely cold climates, concrete can freeze and crack. Meanwhile, excessive heat can lead to quick drying and shrinkage.

Heavy rainfall can also cause your concrete to sink. To manage these issues, you'll need to adjust your leveling methods according to the weather conditions. It's not an easy task, but with the right knowledge and tools, you can make it work.

Can Concrete Leveling Be a DIY Project or Should It Always Be Handled by Professionals?

Sure, you can tackle concrete leveling as a DIY project. However, it's crucial to understand that it's not a simple task. There're specific skills and knowledge required to ensure a safe and effective job.

If you're not confident, it's always best to hire a professional. They've the experience and tools to handle any issues that may arise, which can save you time, effort, and potentially a lot of money in the long run.

Conclusion

Well, there you have it, folks! The top ten thrilling tribulations of concrete leveling, neatly solved for your DIY endeavors. Who knew moisture, shrinkage, and compaction could stir such drama?

But don't fret. Next time your concrete starts acting more high-maintenance than a reality TV star, just remember these handy hacks. With patience and a bit of elbow grease, you'll be the talk of the neighborhood – the concrete whisperer.

Here's to smoother surfaces and zero concrete meltdowns!