Why Do Concrete Leveling Solutions Often Fail?

Concrete leveling fails often due to various reasons. You might overlook actual damage, leading to incomplete repairs. Also, using subpar equipment or low-quality materials might result in poor durability and premature wear. Incorrect installation techniques and environmental factors also contribute to failure. Even inadequate skills or DIY attempts without proper knowledge can lead to costly mistakes. Regular maintenance is key to avoid such failures. Stay tuned, a comprehensive exploration of each factor will help ensure your concrete leveling endeavors are successful in the long run.

Understanding Concrete Leveling Basics

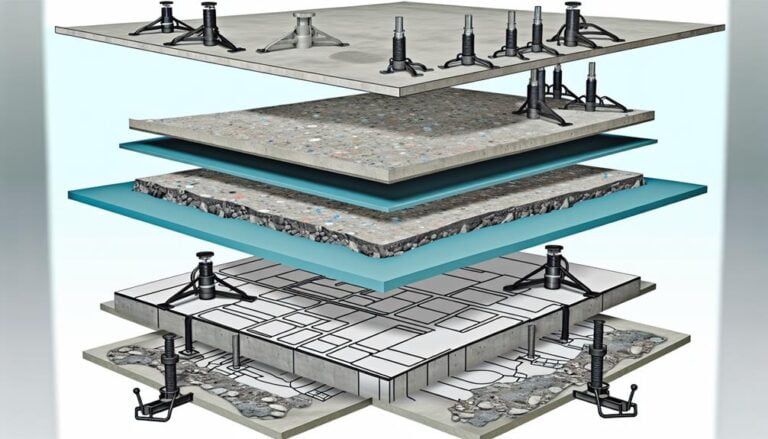

Diving into the world of concrete leveling, you'll quickly learn that it's a critical process in construction, aimed at correcting uneven or sunken concrete surfaces. It's a key step in ensuring the stability of a structure, and it's not something you'd want to take lightly.

Concrete leveling involves injecting a mixture, often made of cement, beneath the concrete slabs to raise them back to their original level. You might think it's a simple task, but there's a lot more to it than meets the eye.

You'll have to consider the condition of the concrete, the type of soil it's sitting on, and the weight the concrete is supporting. Only then can you decide on the right mixture to use, the amount needed, and the exact spots to inject it. It's a delicate balance that requires knowledge, skill, and precision.

But despite the careful planning, things can still go wrong. The mixture mightn't set correctly, the concrete could crack, or the leveling mightn't last. These failures could lead to more serious problems, such as structural damage or even accidents. That's why it's crucial to understand the basics of concrete leveling and to do it right the first time.

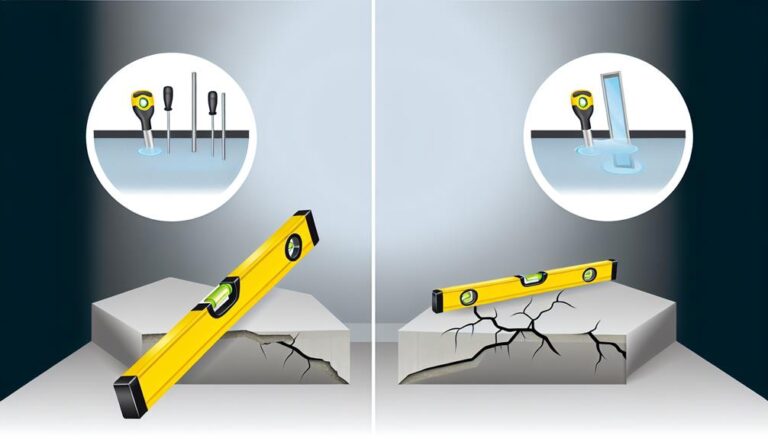

Incorrect Assessment of Damage

Even with the basics in hand, if you misjudge the extent of the damage or the cause, your concrete leveling efforts might not yield the desired results. Incorrect assessment could lead to insufficient or wrong treatment and invariably, failure.

Suppose you underestimate the damage and fill only visible cracks, ignoring hidden ones. You're setting yourself up for failure. Concrete, like any other material, will fail under pressure if not properly repaired. On the other hand, overestimating the damage could lead to unnecessary cost and time wastage.

Here's a table to help you understand the importance of correct damage assessment:

| Incorrect Assessment | Possible Outcome |

|---|---|

| Underestimation | Incomplete repair leading to future damage |

| Overestimation | Unnecessary cost and time spent |

| Ignoring hidden damage | Premature failure of repair |

| Misdiagnosis of cause | Recurring damage after repair |

It's crucial to conduct a comprehensive assessment, determining both the extent and cause of damage. This might require professional help. If you're unsure, don't hesitate to consult a professional. Remember, a well-assessed problem is halfway solved.

Lack of Proper Equipment

Without the right tools, your concrete leveling project is like a ship sailing without a compass, bound for failure. The correct equipment is vital in ensuring a successful result. It's not just about getting the job done, but also about how well it's done.

Lack of proper equipment can lead to inconsistent leveling, poor quality work, and even structural damage to your property. You may think you're saving money by cutting corners on equipment, but in the long run, you're potentially setting yourself up for costly repairs.

Here are a few key pieces of equipment that you shouldn't skimp on:

- A concrete leveling grinder: This tool ensures your surface is flat and smooth. Without it, you could end up with an uneven finish.

- A laser level: This is essential for achieving a perfectly level surface. Guesswork just won't cut it.

- Heavy-duty mixers: These are necessary for mixing your concrete to the right consistency. Improperly mixed concrete can lead to weak and brittle surfaces.

Inadequate Material Quality

Just as you can't build a sturdy house with weak bricks, you can't expect a successful concrete leveling project if you're using subpar materials. Low-quality materials are one of the leading causes of failure in concrete leveling solutions. They might offer short-term savings, but in the long run, they'll cost you more.

Using poor quality concrete, for instance, can lead to a lack of durability. The surface may initially look fine, but over time, it'll start to show signs of wear and tear. Cracks may appear, and sections of the concrete may start to sink, creating uneven surfaces.

Similarly, if the filler material isn't up to standard, it won't provide the necessary support. It mightn't adhere well to the concrete, or it could break down over time. This can lead to the leveling solution failing, with the concrete returning to its uneven state.

To avoid these issues, it's vital to invest in high-quality materials from the outset. Quality materials will provide greater durability and longevity, ensuring that your concrete leveling project is a success. Don't cut corners when it comes to material quality – it's simply not worth the risk.

Faulty Installation Techniques

On top of using quality materials, it's equally important to employ correct installation techniques when leveling concrete. If not, you're setting yourself up for failure right from the start. Faulty installation techniques are a common cause of leveling solutions failing.

One common error isn't properly preparing the surface before applying the leveling solution. Any dirt, loose concrete, or debris can interfere with the bonding process, compromising the integrity of your work.

Another common mistake isn't correctly mixing the leveling solution. If you're too hasty or careless in this step, you could end up with a mixture that's too thin or too thick, which can lead to problems down the line.

Lastly, incorrect application of the solution can lead to an uneven surface or weak spots in the concrete. It's crucial to follow the manufacturer's instructions to the letter to avoid this.

Here's a quick recap of the main points to remember:

- Properly clean and prep the surface before applying the leveling solution

- Carefully mix the solution to the correct consistency

- Follow the manufacturer's instructions for application

Avoiding these common installation mistakes can greatly increase the chances of your concrete leveling project being a success.

Environmental Factors Affecting Leveling

While you're perfecting your concrete leveling technique, don't forget to consider the impact of environmental factors on your project. These factors can significantly affect the leveling process, potentially leading to less-than-ideal results.

Firstly, consider the weather. Rain, humidity, and temperature changes all have a part to play. Rain can erode or wash away the leveling compound before it's fully set, while high humidity can prolong drying and setting times. Conversely, very low temperatures can cause the material to freeze, preventing proper setting.

Next, take into account the soil conditions. The type of soil underneath the concrete slab can impact the leveling process. Sandy soils, for instance, may shift under the weight of the concrete, causing an uneven surface. Clay soils, on the other hand, can expand and contract with moisture changes, leading to slab upheaval or sinking over time.

Lastly, don't overlook the influence of vegetation. Tree roots can grow beneath the slab, causing it to lift and become uneven. In contrast, areas devoid of vegetation may lack the necessary soil stability, leading to subsidence.

In short, don't underestimate these environmental factors. They're crucial in determining the success of your concrete leveling endeavor.

Overlooking Root Cause Analysis

Diving deeper into common concrete leveling failures, it's essential not to overlook conducting a thorough root cause analysis. This step is fundamental to any problem-solving approach. It helps you identify the underlying reasons why your concrete leveling job isn't holding up. You might be quick to blame the materials or the weather, but without a root cause analysis, you're only guessing.

As you delve into this process, keep in mind:

- Don't rush: Root cause analysis isn't a quick fix. It requires time and a detailed examination of the situation. Rushing through it could lead to an inaccurate conclusion.

- Be comprehensive: Look at all possible causes, not just the obvious ones. This means examining everything from the initial planning phase to the finishing touches.

- Keep an open mind: Don't let preconceived notions influence your investigation. You might be surprised at what you find.

Insufficient Expertise and Skills

Even with a thorough root cause analysis, your concrete leveling project can fail if you lack the right expertise and skills. Concrete leveling isn't a simple DIY task. It requires a deep understanding of the material properties, knowledge about the right mixing ratios, and the ability to assess and react to unexpected situations. You might think you're saving money by doing it yourself, but the potential for mistakes can cost you more in the long run.

Many homeowners underestimate the complexity of concrete work. They believe that they can manage it with online tutorials and a bit of elbow grease. Unfortunately, without the right skills, your project's chances of succeeding are slim. It's not just about pouring the mixture and waiting for it to dry. There are numerous factors to consider, such as the weather conditions, the right curing time, and the quality of the materials.

Moreover, an experienced contractor can identify potential problems that you may overlook. They're trained to spot issues like inadequate soil compaction or improper drainage, which can lead to uneven settling and cracking. In the end, it's about having the right skills and expertise to execute the job correctly.

Importance of Regular Maintenance

Regular maintenance of your concrete surfaces isn't just necessary, it's crucial to prevent potential failures and costly repairs. Ignoring the need for routine check-ups and maintenance might result in small issues escalating into significant problems, leading to a complete failure of your concrete leveling solutions.

When you're proactive in maintaining your concrete, you're not just saving money in the long run, but also ensuring the longevity of your surfaces. But what does regular maintenance entail?

- Regular Inspection: Keep an eye out for any signs of cracking or sinking. Early detection is key to preventing further damage.

- Sealing Joints and Cracks: Regularly seal any joints or cracks to prevent water infiltration, which can cause concrete to deteriorate.

- Cleaning: Keep your concrete surfaces clean to prevent the build-up of damaging substances like oil or grease.

Frequently Asked Questions

What Are the Potential Hazards of a Failed Concrete Leveling Project?

If your concrete leveling project fails, you're facing several hazards. You may trip over uneven surfaces, causing injury.

Water can pool in the dips, leading to structural damage or basement flooding.

Further, your property value could decrease.

Lastly, it's not just an eyesore, it can also hint at deeper structural issues.

It's crucial to address any failure promptly and properly to avoid these potential problems.

How Much Typically Does a Professional Concrete Leveling Service Cost?

Imagine opening your wallet and watching dollars flutter out like butterflies. That's what hiring a professional concrete leveling service might feel like. Costs vary depending on the project's size and complexity, but you're typically looking at several hundred to a few thousand dollars.

It's a hefty price, but remember, you're paying for expertise and peace of mind that the job's done right. Always compare quotes and check references before making a decision.

Can Homeowners Undertake Concrete Leveling Tasks Themselves?

Sure, you can undertake concrete leveling tasks yourself, but it's not recommended unless you're an experienced DIYer. It's a complex process requiring specialized tools and skills.

If you don't know what you're doing, you could end up causing more harm than good. It's usually best to hire professionals who know exactly how to handle this type of work.

Are There Any Legal Regulations or Permits Required for Concrete Leveling?

Yes, there are usually local regulations and permits required for concrete leveling. You can't just start this project without proper authorization. It's crucial to check with your local city or county office before beginning.

They'll provide guidelines and necessary paperwork. You're not just ensuring legal compliance, but also your safety and quality of the project.

What Are Some Indicators That a Concrete Leveling Solution Is About to Fail?

You might notice several signs indicating a failing concrete leveling solution. Cracks reappearing or widening, sinking or settling concrete, and uneven surfaces are common indicators.

If you're seeing water pooling in certain areas, that's a red flag too.

It's important to act swiftly in these situations. Consult a professional immediately to prevent further damage and to determine the best repair strategy.

Conclusion

So, just as the Titanic's fate was sealed by overlooking an iceberg, your concrete leveling solution can fail due to a myriad of overlooked factors. From incorrect damage assessment and inadequate material quality to skipping root cause analysis, these pitfalls can sink your project.

Add in environmental factors and a lack of expertise, and you've got a recipe for disaster. Remember, regular maintenance isn't a luxury, it's the lifeboat that keeps your concrete afloat.